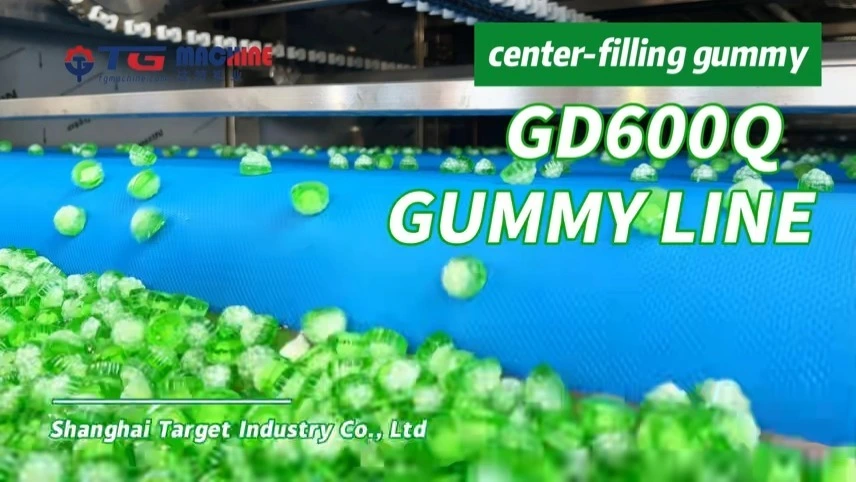

Umugqa wokukhiqiza uswidi we-Gummy GD600Q

I-GD600Q Automatic Gummy Production System iyisisetshenziswa esikhulu esikhiphayo, Ifakwe izinsimbi ezizenzakalelayo zokukala kanye nokudla okuzenzakalelayo, ethuthukisa ngempumelelo ukusebenza kahle kwemishini futhi yehlise izindleko zabasebenzi ngenkathi iqinisekisa ukuphuma okukhulu, Ingakhiqiza ama-gummies afika ku-240,000* ngehora, kufaka phakathi yonke inqubo yokupheka, ukufaka nokupholisa, Ilungele ukugijima okukhulu kokukhiqiza

Incazelo Yezisetshenziswa

Isistimu yokuxuba ijeli ye-Pectin

Kuyisithako esizenzakalelayo sohlelo lwesisindo nokuxuba lwe-pectin slurry yokupheka kwangaphambili kwesixazululo se-confectionery. Impushana ye-pectin, amanzi, nempushana kashukela ihlanganisa ukufakwa. Ngenkathi isindisa abasebenzi, iphinde ixazulule kahle umehluko wekhwalithi yamaqebelengwane amaswidi abangelwa izithako zokwenziwa. Ithangi lensimbi elilodwa lesisindo elifakwe kumaseli omthwalo amathathu anosayizi wesisindo senqwaba esingu-180kg.

Ngemuva kokuthi isisindo sesiphelile, zonke izinto zizongena kumpheki ofakwe ibhantshi nge-shear yesivinini esikhulu ukuze kuqedwe ngokugcwele i-pectin powder kanye noshukela oyimpuphu. Uma izithako eziphelele zifakwe emkhunjini, emva kokuxuba, isiraphu izobe idluliselwa ku-tank yokubamba ezinye izixazululo. Ithangi lokugcina lakhiwe njengomkhumbi wokubamba uketshezi olushisayo noma olubandayo kanye nama-slurries. I-stirrer yensimbi engagqwali, Isisekelo esizidonsela amanzi ngomsele, Uhlaka lwensimbi engagqwali lungawashwa ngokuqondile ngamanzi, Lufakwe ijakhethi lokufudumeza, Izinhlangothi ezivalekile. Wonke amapayipi afakwe izihlungi ze-tubular, ezingasefa ukungcola oketshezini ukuze kuqinisekiswe ukuthi isiraphu ihlanzekile futhi ihlanzekile futhi ihlangabezana nezindinganiso zempilo nokuphepha. amaresiphi afika kwayishumi asethiwe agcinwe ohlelweni lokulawula lwe-PLC.

Isiraphu kanye nejeli yesisindo kanye nohlelo lokuxuba

Inqubo iqala ngokukala nokuxuba izithako eziyinhloko namanzi, impushana kashukela, ushukela, nejeli encibilikisiwe. Izithako ziphakelwa ngokulandelana ethangini lesisindo se-gravimetric kanye nokuxuba futhi nenani lesithako ngasinye esilandelayo liyalungiswa ngokuya ngesisindo sangempela salezo ezandulele. Ngale ndlela ukunemba kwe-0.1% kufinyelelwa, ukuze kuqinisekiswe ikhwalithi nokuvumelana kuyagcinwa.

Kungenzeka ukwengeza izithako ezisebenzayo kulesi sigaba inqobo nje uma izinga lokushisa lizinzile kodwa ekusebenzeni, kunesizathu esincane kakhulu sokwenza kanjalo. Iqoqo ngalinye lezithako lixutshwa ku-slurry bese liphakelwa ethangini le-reservoir elihlinzeka ngokuphakelayo okuqhubekayo kumpheki. Umjikelezo wokukala nokuxuba uzenzakalela ngokugcwele futhi amarekhodi aphelele awo wonke amaqoqo ayatholakala ohlelweni lokulawula, ngokuqondile noma ngenethiwekhi yefekthri.

Umpheki Oqhubekayo Wokukhulisa Ifilimu

Ukupheka kuyinqubo enezigaba ezimbili ezibandakanya ukuncibilikisa ushukela ogqamile noma isomalt

kanye nokuhwamulisa isiraphu engumphumela ukuze kuzuzwe okuqinile kokugcina okudingekayo. Ithini lokupheka

kugcwaliswe ku-cooker okuyigobolondo ne-tube design enama-scrapers. Lena idivayisi elula yesitayela se-venturi ebeka isiraphu ephekiwe ekwehleni okungazelelwe kwengcindezi, okubangela ukuthi umswakama owedlulele unyamalale. Isiraphu ephekwe kancane ingena ku-Microfilm cooker. Lesi umpheki wefilimu ophakamisayo ohlanganisa ishubhu elishisisa ngesitimu phansi ngaphakathi lapho isiraphu idlula khona. Ingaphezulu leshubhu lokupheka likhuhla uchungechunge lwama-blades ukwenza ifilimu elizacile kakhulu lesiraphu elipheka esikhathini esingangemizuzwana njengoba lidlula ngeshubhu lingena egumbini lokuqoqa.

Izinga lokushisa lokupheka liyancishiswa ngokubamba umpheki ngaphansi kwe-vacuum. Ukupheka okusheshayo e- izinga lokushisa eliphansi kakhulu elingaba khona libaluleke kakhulu ukuze kugwenywe ukuwohloka kokushisa kanye nokuguqulwa kwenqubo lokho kunganciphisa ukucaca futhi kuholele ezinkingeni zempilo yeshelufu njengokunamathela nokugeleza okubandayo.

I-CFA kanye nesistimu yokuxuba izithako ezisebenzayo

Imibala, ama-flavour, kanye ne-asidi (CFA) yengezwa kusiraphu ngokuqondile ngemva kompheki futhi kungalesi sikhathi lapho izithako ezisebenzayo ngokuvamile zizongezwa kusetshenziswa uhlelo olufanayo.

Isistimu yokwengeza ye-CFA eyisisekelo ihlanganisa ithangi lokubamba kanye nephampu ye-peristaltic. Izinketho zokuxuba, ukushisisa kanye nokujikeleza kabusha kungase kwengezwe ethangini lokubamba ukuze kugcinwe izengezo zisesimweni esihle kuyilapho iluphu yokulawula i-flowmeter ingase yengezwe epompo ukuze kube nokunemba okukhulu. Engeza zonke izithako ngesistimu yokukala, enamathangi angu-2 afakwe inzwa, yenza imibala emi-2 ibe nokwenzeka, isistimu yokukala yenza inani lezithako linembe kakhudlwana, imiphumela yokuxuba ngeke ithikamezeke ngokuhlukahluka kwamandla kagesi noma ukugeleza okuhlukahlukene noma izindlela zokupheka ezihlukene, Amathangi ama-2 angenza umbala we-2 noma isikhungo sigcwaliswe, isikhathi sokuxuba singama-3-5min ngevolumu ye-40-50L.

Idiphozithi Nokupholisa Iyunithi

I-depositor ihlanganisa ikhanda elifaka idiphozi, isifunda sesikhunta, nomhubhe wokupholisa. Isiraphu ephekiwe ibanjelwe ku-hopper eshisayo efakwe inombolo enkulu 'yamasilinda epompo' - eyodwa ngediphozithi ngayinye. Uswidi udonselwa emzimbeni wesilinda sepompo ngokunyuka kwepiston ukuya phezulu bese iphushwa ngevalvu yebhola ku-stroke ebheke phansi. Isekhethi ebunjiwe ihamba ngokuqhubekayo futhi lonke ikhanda elifakayo libuyela emuva naphambili ukuze lilandelele ukunyakaza kwalo. Konke ukunyakaza ekhanda kuqhutshwa i-servo ukuze kube nokunemba futhi kuxhunywe ngomshini ukuze kulingane. Umhubhe wokupholisa onamaphasi amabili utholakala ngemva komfaki-mali ngokukhishelwa ngaphansi kwekhanda lomuntu ofake imali. Ukuze uthole uswidi, umoya we-ambient udonswa efekthri futhi usakazwe emhubheni uchungechunge lwabalandeli. Ojeli ngokuvamile badinga ukupholisa okuthile esiqandisini. Kuzo zombili izimo, lapho amaswidi ephuma emhubheni wokupholisa asuke esesimweni esiqinile sokugcina.

Isikhunta esinethuluzi elikhishwa ngokushesha

Isikhunta singaba yinsimbi ngentokozo engagxili noma irabha ye-silicone ekhishwa ngomshini noma komoya. Zihlelwe ngezigaba ezingasuswa kalula ekushintsheni imikhiqizo, nokuhlanza ukugqoka.

Ukuma kwesikhunta: Kungenziwa ngokwezifiso

Isisindo se-Gummy: Ukusuka ku-1g kuya ku-15g

Izinto zokubumba: Isikhunta esiboshwe nge-Teflon

imininingwane yomkhiqizo