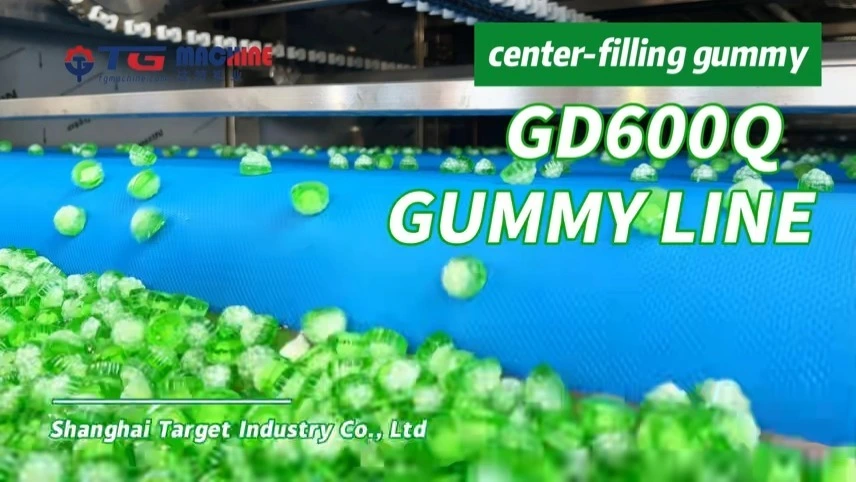

Gummy candy kugadzira mutsara GD600Q

GD600Q Automatic Gummy Production System ihombe yekuburitsa midziyo, Yakashongedzerwa neatomatiki kuyeresa uye otomatiki yekudyisa zvishandiso, izvo zvinonyatso kunatsiridza kushanda zvakanaka kwemidziyo uye kuderedza mutengo wevashandi nekuona yakakura kubuda, Inogona kugadzira anosvika mazana maviri nemakumi mana ezviuru * gummies paawa, kusanganisira iyo yese maitiro ekubika, kuisa uye kutonhora, Iyo yakakwana kune yakakura kugadzirwa inomhanya

Equipment Description

Pectin gel kusanganisa system

Icho chigadziro che otomatiki chinoyera uye kusanganisa system ye pectin slurry pre-kubika ye confectionery mhinduro. Iyo pectin hupfu, mvura, uye shuga hupfu zviri kusanganisa kuisa. Ndichiri kuchengetedza basa, zvakare inogadzirisa zvakakwana mutsauko mumhando yemabhechi ezvihwitsi anokonzerwa neanogadzira zvigadzirwa. Simbi imwechete inoyera huremu tangi yakaiswa pamaseru matatu akaremerwa ane huremu hwe180kg.

Mushure mekuyera kwapera, zvinhu zvese zvinopinda mubiki ane jaketi ane high-speed shear kunyungudutsa zvizere pectin hupfu uye shuga yehupfu. Kamwe chete izvo zvese zvinongedzo zvinodyiswa mumudziyo, mushure mekusanganiswa, sirasi inobva yaendeswa kune tangi yekubata kune mamwe mhinduro. Iyo tangi yekuchengetera yakagadzirirwa semudziyo wekubata wezvinopisa kana kutonhora zvinwiwa uye slurries. Stainless steel stirrer, Self-draining base, Stainless steel framework inogona kugezwa yakananga nemvura, Jacketed for heat, Insulated mativi. Mapombi ese ane tubular mafirita, anogona kusefa tsvina mumvura kuti ave nechokwadi chekuti sirasi yakachena uye ine hutsanana uye inosangana nehutano nekuchengetedza zviyero. anosvika gumi pre-set mabikirwo akachengetwa paPLC control system.

Syrup uye Gel Kuyera uye Kusanganisa System

Maitiro acho anotanga nekuyera nekusanganisa izvo zvakakosha zvinongedzo nemvura, hupfu hweshuga, glucose, uye gel yakanyungudika. Izvo zvinongedzo zvinodyiswa zvakatevedzana mugiravimetric inoyera uye yekusanganisa tangi uye huwandu hwechimwe nechimwe chinotevera chinogadziriswa zvinoenderana nehuremu chaihwo hwezvakapfuura. Nenzira iyi kurongeka kwe0.1% kunowanikwa, kuve nechokwadi chemhando uye kusimba kunochengetwa.

Zvinokwanisika kuwedzera zvinhu zvinoshanda panguva ino kunze kwekuti ivo vakagadzikana kupisa asi mukuita, pane chikonzero chidiki chekuita kudaro. Batch yega yega yezvinwiwa inosanganiswa mune slurry uye yobva yapihwa kune reservoir tank iyo inopa inoenderera yekudyisa kumubiki. Kuyera uye kusanganisa kutenderera kwakazara otomatiki uye akazara marekodhi ebatch yega yega anowanikwa kubva kune control system, ingave yakananga kana pamusoro pefekitori network.

Yepamberi Kusimudza Firimu Rinoenderera Mubiki

Kubika idanho rematanho maviri rinosanganisira kunyungudutsa shuga yegranulated kana isomalt

uye kufefetedza sirapu inobuda kuti uwane iyo inodiwa yekupedzisira yakasimba. Kubika gaba

kuzadzikiswa mubiki iyo iri shell uye chubhu dhizaini ine scrapers. Ichi chishandiso chiri nyore che venturi chinoisa sirapi yakabikwa kudonha kamwe kamwe mukumanikidza, zvichiita kuti hunyoro hwakawandisa hudzike. Sirasi yakabikwa zvishoma inopinda muMicrofilm cooker. Ichi chibiki chemufirimu chinosimudza chinosanganisira chubhu-inodziya chubhu pasi mukati iyo iyo sirasi inopfuura. Pamusoro pemubiki chubhu inokweshwa nenhevedzano yemablades kuti iite firimu rakatetepa remushonga rinobika mukati memasekondi mashoma sezvo richipfuura nechubhu kupinda mukamuri yekuunganidza.

Kupisa kwekubika kunoderedzwa nekubata cooker pasi pevacuum. Kubika nekukurumidza pa tembiricha yakadzikira zvakanyanya yakakosha kudzivirira kudzikisira kupisa uye kuita inversion izvo zvinoderedza kujeka uye zvinotungamira kumatambudziko ehupenyu hwesherufu sekunamira uye kutonhora kuyerera.

CFA uye inoshanda zvinosanganisa kusanganisa system

Mavara, zvinonaka, uye asidhi (CFA) zvinowedzerwa kune sirasi zvakananga mushure memubiki uye panguva ino izvo zvinoshandiswa zvinoshandiswa zvinowanzowedzerwa uchishandisa nzira yakafanana.

Iyo yakakosha CFA yekuwedzera sisitimu inosanganisira tangi yekubata uye peristaltic pombi. Kusanganisa, kudziyisa uye kudzokorodza sarudzo dzinogona kuwedzerwa kune tangi rekubata kuchengetedza iyo yekuwedzera iri muchimiro chakanyanya ukuwo flowmeter control loop inogona kuwedzerwa kune pombi yekunyatsoita. Wedzera zvese zvinongedzo nekuyera sisitimu, ine matangi maviri akashongedzerwa sensor, ita kuti mavara maviri agoneke, kuyera sisitimu inoita kuti huwandu hwezviyo hwuve hwakajeka, mhedzisiro yekusanganisa haikanganiswe nekusiyana kwevoltage kana kuyerera kusiyanisa kana akasiyana mabikirwo, 2 matangi anogona kuita 2 ruvara kana nzvimbo yakazadzwa, nguva yekusanganiswa ndeye 3-5min nehuwandu hwe40-50L.

Depositing Uye Kutonhora Unit

A depositor inosanganisira yekuisa musoro, mold circuit, uye kutonhora tunnel. Sirasi yakabikwa inobatwa muhopi inopisa yakaiswa nhamba huru ye 'pump cylinders' - imwe yega yega yega. Maswiti anokweverwa mukati memuviri wepombi yepombi nekukwira kumusoro kwepiston yobva yasaidzirwa nemuvharuvhu yebhora pazasi sitiroko. Dunhu rakaumbwa rinoramba richifamba uye musoro wese wekuisa unodzokera kumashure nekudzoka kuronda mafambiro ayo. Mafambiro ese ari mumusoro anofambiswa neservo kuti anyatsoita uye akabatana nemakanika kuitira kuenderana. A maviri-chipfuura kutonhora mugero iri pashure depositor pamwe ejection pasi depositor musoro. Nekune zvihwitsi, mhepo yakadzikama inodhonzwa kubva mufekitori uye inotenderedzwa nemugero nenhevedzano yevateveri. Jellies kazhinji inoda kutonhora kwefiriji. Muzviitiko zvese izvi, kana zvihwitsi zvabuda kubva mugero rekutonhodza zvinenge zvave kusimba kwekupedzisira.

Molds ine kukurumidza-kuburitsa chishandiso

Molds inogona kuve yesimbi ine isina-tsvimbo yekupotera kana silicone rabha ine mechanical kana mhepo ejection. Izvo zvakarongwa muzvikamu zvinogona kubviswa nyore nyore pakuchinja zvigadzirwa, uye kuchenesa coating.

Mold chimiro: Inogona kugadzirwa

Gummy uremu: Kubva 1g kusvika 15g

Mold zvinhu: Teflon yakavharwa mold

product details