Die formed hard candy and lollipop candy production system

YT-200: The fully automatic hard candy production system is a production line with diverse functions, which can produce hard candies of different sizes, shapes and weights.

With a maximum output capacity of 200-1000kg/h of hard candy, this die-formed hard candy production line is designed to produce various shapes of candies utilizing different molds.

Which includes the entire process of cooking, die-formed and cooling

The electric heating cooker precisely controls the heating time and temperature which results in candy that is more transparent and flavorful. The production line is equipped with an advanced hard candy former that effectively ensures size consistency and minimizes material waste.

The entire production line is produced in a manner that meets GMP and food hygiene requirements. This will make it easier for your company to pass various certifications including GMP, QS, HACCP, etc.

Equipment Description

Cooking System

This is an automatic system for dissolving and mixing ingredients. After the sugar, glucose and any other raw materials needed are mixed into syrup in the vessel, it is transferred to the holding tank for continuous production. The entire process of cooking is controlled by a control cabinet which is separate for convenient working.

The processing of the system is continuous cooking and vacuum effecting.

Optimal heat exchange, makes the cooking well and evenly.

Central operation and control from the cabinet, easily operation and maintains.

Discharging by pump or free discharging is available for different processing.

Water cycling style vacuum pump and big chamber makes the better control of moisture and temperature of the final cooked mass.

Die-Formed And Cooling Unit

Die-formed forming system consists of Batch roller, Rope sizer, Lollipop forming machine, Transporting conveyor, Cooling tunnel.

The cooked sugar dough goes through a Batch roller shaping it into a cone by means of an alternating and programmable rolling action. Sugar mass gradually funnels, in the final section, into a rope that can properly feed a rope sizer.

The rope sizer is designed to receive a thick candy/ toffee/ gum rope from either an extruder or a batch roller and to size it down to the desired rope section.

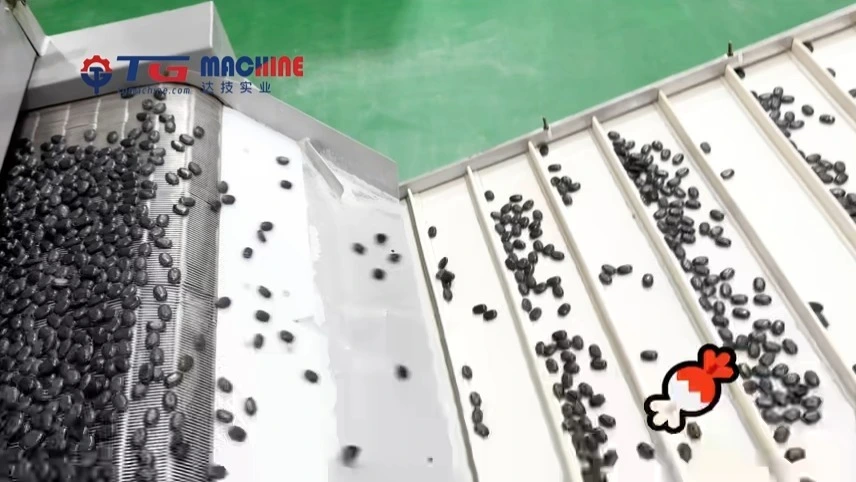

The Die -formed machine is the ideal solution when it comes to the production of formed hard boiled candies and sweets (unfilled, filled with liquid and/ or powders or paste). The rotary-die technology is able to deliver perfectly-formed, seamless and burr-free candies, lozenges and centres.

The formed candy is sent to the cooling tunnel through the conveyor belt for the final cooling step.

Product Details