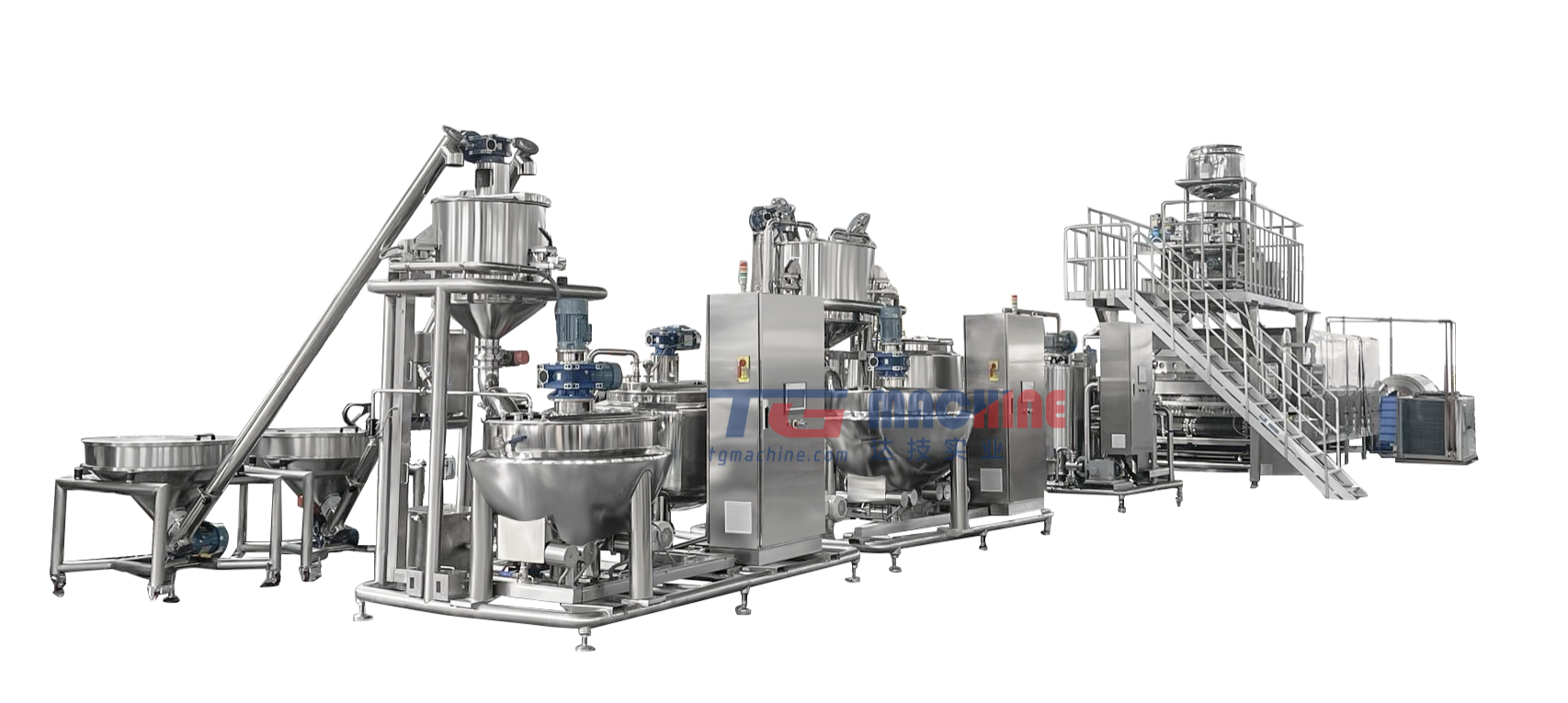

TGmachine Sets New Standard in Confectionery Manufacturing with Launch of Fully-Automated, High-Efficiency Gummy Candy Production Line

Uncompromising Quality and Precision at Every Stage

The heart of the line is TGmachine’s advanced, PLC-controlled cooking and mixing system. Utilizing precise temperature and vacuum control, it creates a perfect gelatin or pectin-based syrup batch with optimal texture, clarity, and flavor retention. This system ensures each batch is identical, eliminating the variability that can plague traditional methods.

Following preparation, the syrup is conveyed to the industry-leading depositor. This machine is a marvel of engineering, capable of handling multiple recipes, colors, and shapes simultaneously with pinpoint accuracy. Its high-speed, volumetric piston pumps ensure each candy mold is filled with exceptional consistency in weight and shape, minimizing waste and maximizing yield. The depositor is designed for quick mold changes and easy cleaning, supporting manufacturers in producing small, customized batches alongside large-scale runs without costly downtime.

Intelligent Cooling and Gentle Finishing

After depositing, the candies enter TGmachine’s cooling tunnel. This stage is critical for developing the perfect gummy texture. The tunnel features independent, precisely controlled zones for temperature, humidity, and airflow, allowing for a customized cooling curve tailored to specific recipes. This intelligent system guarantees uniform setting and moisture content across all products, resulting in a perfect chew and extended shelf life.

The demolding process is fully automated. The line features a gentle, shock-free demolding system that expertly separates even the most delicate candies from their aluminum alloyed or silicone molds without damage or deformation. For producers requiring a non-stick finish or a sugary coating, the line integrates seamlessly with TGmachine’s polishing and sanding drums. These drums use a controlled, tumbling action to apply oil, wax, or a fine layer of sugar evenly and gently, giving the candies a brilliant, professional sheen or a classic sanded finish.

Built for the Future: Smart Manufacturing and Sustainability

Understanding the needs of modern factories, TGmachine has embedded smart manufacturing principles into the line. The entire system can be monitored and adjusted from a central human-machine interface (HMI) panel, providing real-time data on production speed, temperatures, and system status. Predictive maintenance alerts help prevent unplanned stoppages, while detailed production reporting aids in quality control and operational analysis.

Sustainability is also a core design consideration. The line incorporates energy-efficient motors, optimized thermal systems to reduce power consumption, and designs that minimize water and raw material waste.

About TGmachine

TGmachine (www.tgmachine.com) is a globally recognized manufacturer specializing in high-quality machinery for the food, pharmaceutical, and chemical industries. With decades of experience and a relentless focus on R&D, TG Machine provides reliable, innovative, and cost-effective processing solutions to clients worldwide. The company’s commitment to customer support—from initial design and installation to comprehensive after-sales service and training—ensures partners achieve their production goals and grow their businesses.